Electrical discharge metal cutting.

This method of metal processing involves cutting a metal product using electrical discharges that occur between an electrode in the form of a wire and the surface of the part. Metal electroerosion processing is used to process parts in those places that cannot be processed by milling. If you need to make a deep hole in a metal part or cut a large thickness with a complex contour, then the most optimal method in this case is to use electrical discharge machining. The use of this technology also ensures high cutting accuracy. Electrical erosion allows you to solve various problems where the use of other technologies is impossible or impractical for technical or economic reasons. A wire EDM machine uses small-diameter wire as an electrode, which creates a cut along a given contour. The wire is made from metals such as molybdenum

or tungsten, these metals are heat-resistant. This processing method is used in cases where it is necessary to produce parts with increased accuracy.

Advantages of electrical discharge machining:

- Any conductive materials with different characteristics are processed: hard, durable, viscous and brittle, etc. ;

- Ability to cut expensive alloys and materials along complex contours, with a minimum cutting width;

- Possibility of processing deep holes, including in hard-to-reach places;

- Due to the absence of mechanical impact on the material, processing of thin-walled and non-rigid parts is possible;

- An alternative to milling in cases where milling cannot be processed;

Discuss the project

Clicking on the "Send" button, you consent to the processing of personal data and agree to the privacy policy.

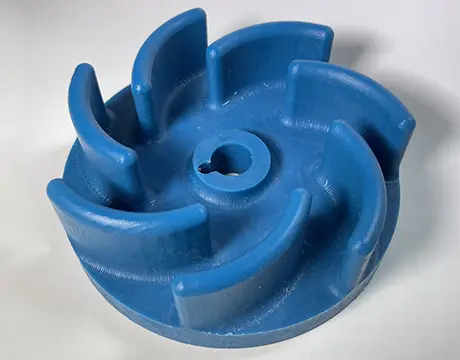

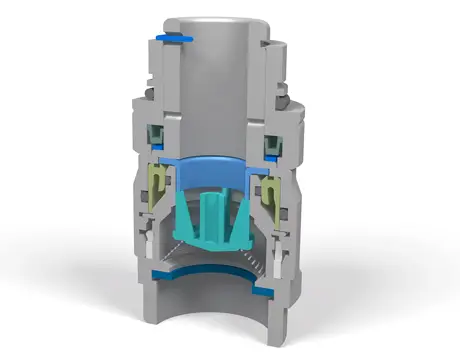

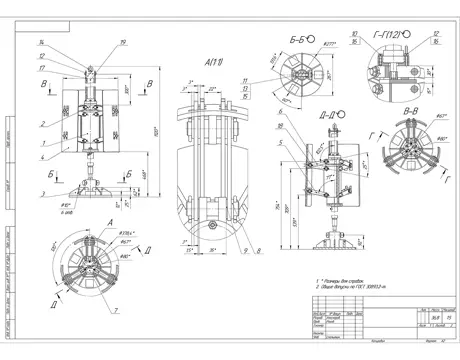

Examples of previous works

Back call

If you have any questions, you can request a call back and our specialists will advise you on all your questions.

Clicking on the "Call me back" button, you consent to the processing of personal data and agree to the privacy policy.