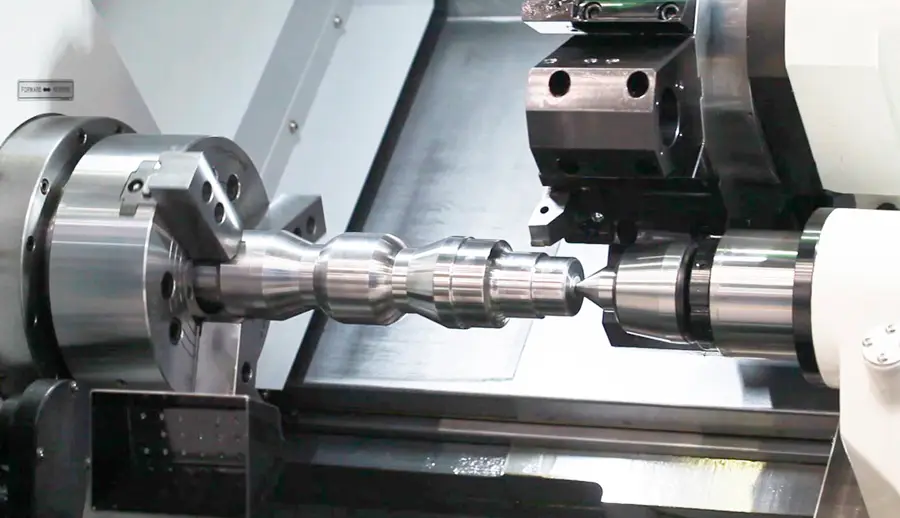

Turning work on CNC machines.

Turning is one of the methods of processing products by cutting off an excess layer of material from a workpiece to obtain the required shape, size and roughness. Turning is carried out on lathes. During turning, parts such as bodies of revolution are made: shafts, screws, pulleys, bushings, rings, couplings, nuts, etc. The main types of work performed during turning are: processing of cylindrical, conical, shaped, end surfaces; turning grooves; cutting operations; drilling holes, boring, countersinking, reaming; thread cutting. Turning work is performed on CNC machines. Such machines allow the production of high-quality products with increased precision, thanks to computer programming of the turning process. Our company performs all types of turning work, including drilling holes, threading, boring and reworking existing

products. We perform turning on modern machines, which allows us to work with workpieces of any configuration: shafts, rings, gears, bushings, and parts of complex geometry.

Factors influencing the cost of turning work:

- Dimensions of the workpiece and the final product;

- Features of the processed material;

- Order quantity;

- Urgency;

List of basic materials processed by turning:

- Aluminum;

- Copper;

- Brass;

- Bronze;

- Steel;

- Engineering plastics (fluoroplastic, rimamide, polyacetal, etc.). A type of plastic that, in terms of its thermal, mechanical and technological characteristics, can replace metals;

Discuss the project

Clicking on the "Send" button, you consent to the processing of personal data and agree to the privacy policy.

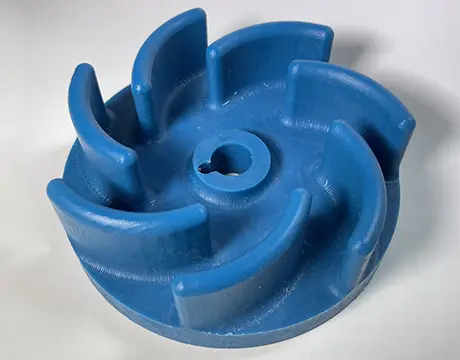

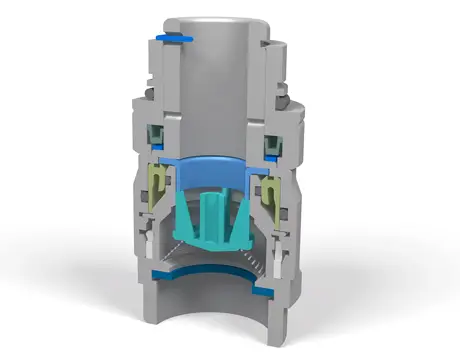

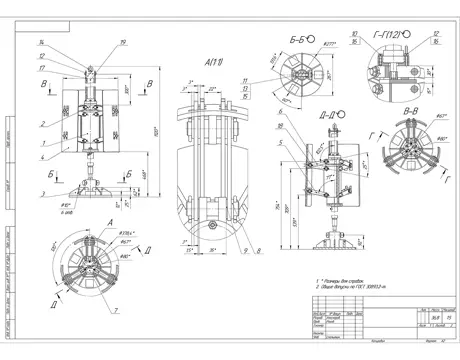

Examples of previous works

Back call

If you have any questions, you can request a call back and our specialists will advise you on all your questions.

Clicking on the "Call me back" button, you consent to the processing of personal data and agree to the privacy policy.