Prototyping of products and constructions.

Before launching a product into mass production or before releasing a large batch, a prototype is almost always required. Prototyping is the rapid creation of a draft version of a product with full basic functionality and geometry of the future final version, for a detailed analysis of the correctness of the work. In the process of prototyping, a working system is created with little effort (it is possible that the prototype will be ineffective, with errors, and incomplete). When prototyping, a detailed picture of the structure of a product or product is clearly visible. Prototyping, according to many manufacturers, is the most important stage in product development. After the prototyping stage, product adjustment stages usually follow to create and test the final product. Our

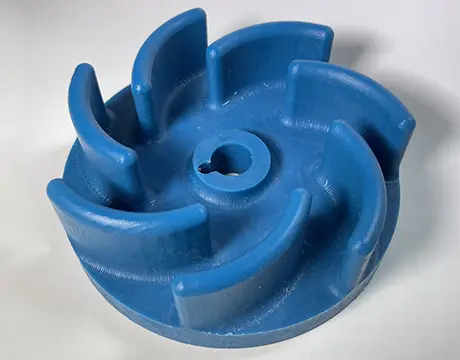

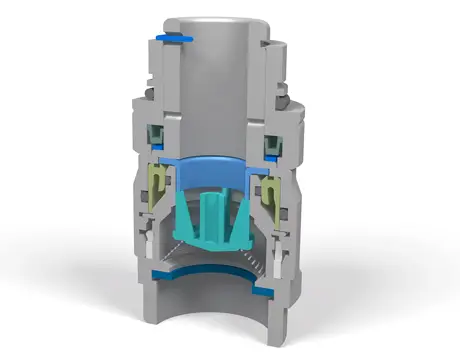

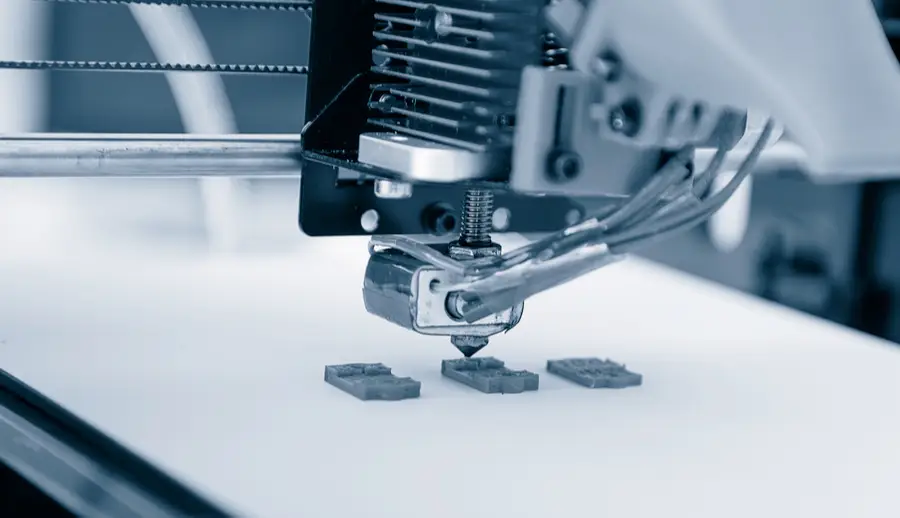

production facilities and experienced design department allow our company to create prototypes of new and non-standard products, as well as models of complex geometries. Using of a technologically advanced fleet of machines, as well as 3D printing technology, ensures high quality of the resulting prototype while reducing labor costs and saving material resources.

List of works performed during product prototyping:

- Development of 3D model in CAD;

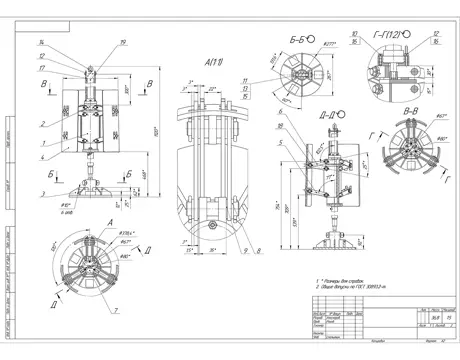

- Development of blueprints;

- Manufacturing of individual product parts on metalworking machines or a 3D printer;

- Manufacturing of a complete prototype construction;

Discuss the project

Clicking on the "Send" button, you consent to the processing of personal data and agree to the privacy policy.

Examples of previous works

Back call

If you have any questions, you can request a call back and our specialists will advise you on all your questions.

Clicking on the "Call me back" button, you consent to the processing of personal data and agree to the privacy policy.