Laser cutting of round and profile pipes.

Laser cutting of profile and round pipes is a modern, high-speed, and high-precision technology for cutting pipes of all types. Compared to conventional sawing and drilling, laser pipe cutting has two tangible advantages: speed and accuracy. The cutting element is a high-power laser beam. When laser cutting a pipe, it is not subjected to any mechanical stress. This allows you to cut even the thinnest pipes that are subject to deformation, without the risk of damage or crushing. All of the above factors make it possible to perform laser cutting of profile and round pipes on favorable terms for customers, ensuring high quality of the product and completion of work in a short time. Laser cutting of pipe blanks is carried out on computer numerical control (CNC) machines. A pre-created program is loaded into the machine, which

ensures complete automation of the process and elimination of errors. Pipe laser cutting provides maximum cutting accuracy, regardless of the length and shape of the pipe.

Factors influencing the cost of laser cutting of profile and round pipes:

- Order volume. Laser cutting of pipes includes preliminary setup of the machine. When ordering a small batch or single copies, the cost of the service may increase significantly compared to a large batch;

- Features of the metal or alloy, as well as factors such as labor intensity, complexity of pipe geometry, non-standard contours and holes. Workpiece wall thickness;

- Urgency;

The main advantages of laser cutting of profile and round pipes:

- Cutting pipes from various materials: stainless steel, cast iron, copper, titanium, brass, aluminum;

- Possibility of cutting workpieces of non-standard shapes;

- Possibility of figure cutting, marking and engraving. The laser allows for technical engraving and perforation with minimal-sized holes;

- Significant cost reduction due to the exclusion from the technological process of such stages as drilling holes, milling and sawing;

- After laser cutting, the pipe is immediately ready for use in the structure;

- No burrs or deformations on the treated surface;

Discuss the project

Clicking on the "Send" button, you consent to the processing of personal data and agree to the privacy policy.

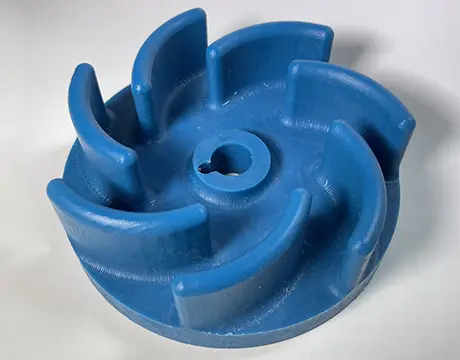

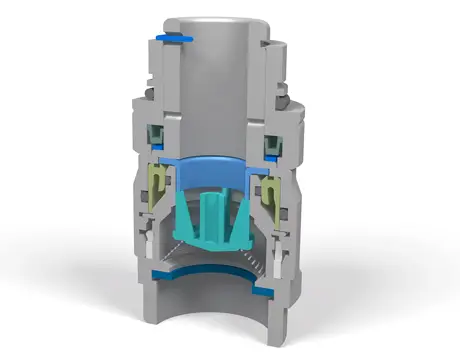

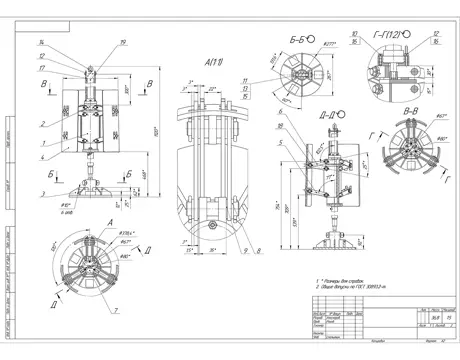

Examples of previous works

Back call

If you have any questions, you can request a call back and our specialists will advise you on all your questions.

Clicking on the "Call me back" button, you consent to the processing of personal data and agree to the privacy policy.