Milling of metals, plastics and wood.

Milling is a type of mechanical processing of material in which the workpiece is exposed to the action of a special cutting tool - a mill. Rotating at high speed in accordance with a given trajectory (when using CNC machines), the cutting tool cuts material. Milling processing is used for the manufacture of steel and plastic products that are in demand in mechanical engineering, instrument making, aircraft manufacturing and many other areas. Modern milling methods make it possible to produce complex parts, increasing production volume, reducing effort and costs, and also reducing the rejection rate. Milling is carried out on CNC machines. Such machines allow the production of high-quality products with increased precision, thanks to computer programming of the milling process. Our organization processes parts on 3- and 4-axis machines.

Factors influencing the cost of milling work:

- Number of technical parameters (surface roughness, milling accuracy, etc.). The more stringent the requirements for processing parameters, the higher the cost of milling will be;

- Time required to complete the order. The time frame is determined by the specifics of the material being processed and the dimensions of the product;

- Urgency;

List of basic materials processed by milling:

- Aluminum. Products made from this metal and its alloys lend themselves well to milling and are widely in demand in various industries, as well as in design and decorative elements. Aluminum is a lightweight and ductile metal, which allows milling to produce products of complex geometry and high precision;

- Copper. Widely used in medicine, electrical industry, mechanical engineering, etc. Due to the high ductility of copper, you can encounter some difficulties during milling; this problem is solved by choosing the appropriate cutting tool and correct cutting conditions;

- Brass. Corrosion-resistant, plastic and durable material. Due to its qualities, it is widely in demand in heavy industry, instrument making, as well as in the manufacture of designer products;

- Bronze. It is used in aircraft manufacturing, instrument making, machine tool manufacturing, as well as design products. Very convenient materials for milling, which allows you to produce parts of the most complex geometries;

- Steel. A metal that is a compound of iron and carbon. Most products in the fields of mechanical engineering, medicine, electronics, etc. are made from steel. Metal milling allows you to create parts of different shapes and geometries;

- Engineering plastics (fluoroplastic, rimamide, polyacetal, etc.). A type of plastic that, in terms of its thermal, mechanical and technological characteristics, can replace metals;

Discuss the project

Clicking on the "Send" button, you consent to the processing of personal data and agree to the privacy policy.

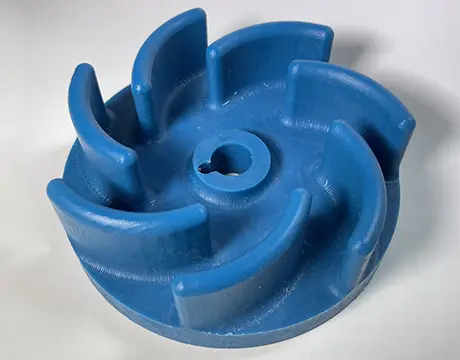

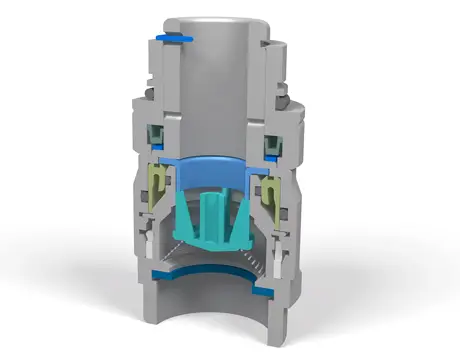

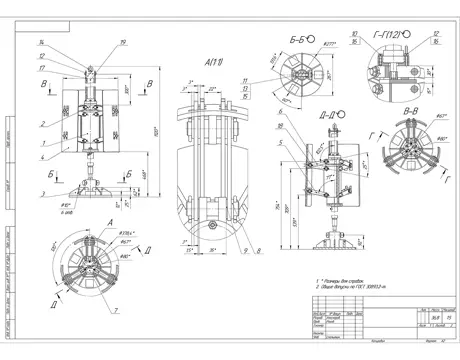

Examples of previous works

Back call

If you have any questions, you can request a call back and our specialists will advise you on all your questions.

Clicking on the "Call me back" button, you consent to the processing of personal data and agree to the privacy policy.