Reverse engineering.

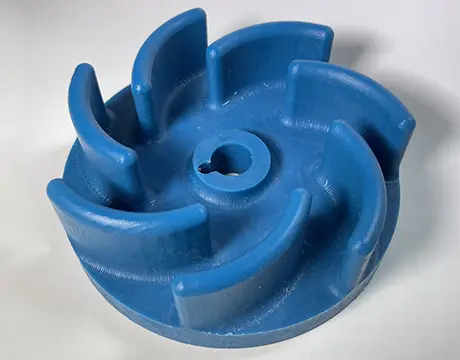

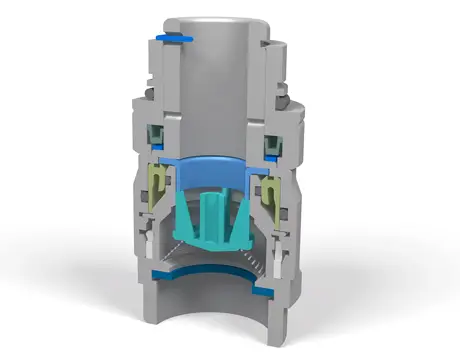

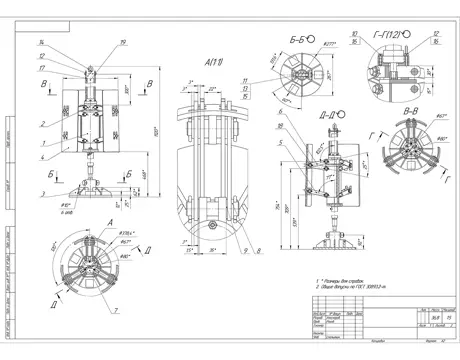

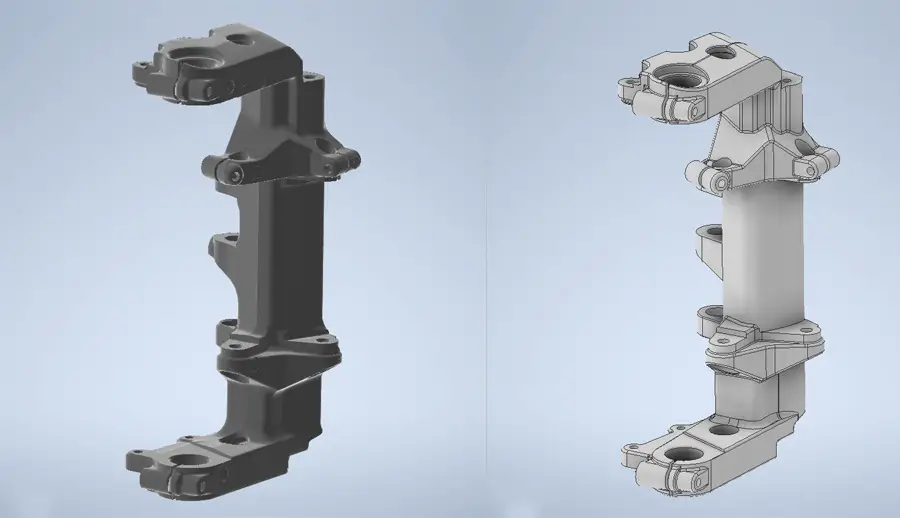

Reverse engineering is the process of creating the most accurate or, depending on the situation, approximate copy of an object based on an existing model that has similar physical characteristics. In simple terms, reverse engineering is the copying of various mechanisms, machines and products without actually developing them. This allows you to reproduce a successful copy with minimal time. Quite often, during reverse engineering, it is still necessary to make changes to the design, which may be caused by differences in production technology or the elimination of shortcomings of the original. In the modern world, reverse engineering is directly related to the development of three-dimensional scanning technology for objects. Using 3D scanning technology, the full volume of data on the geometry of a product

can be transferred by a model file in STL format. After this, based on the STL model, designers recreate this model into a solid 3D CAD model in specialized CAD systems. Quite often, when copying various simple parts, design documentation may not be developed at all, and the resulting STL model, after scanning, is immediately sent for processing on CNC machines.

The main areas of work performed by our company in the field of reverse engineering:

- Creating a 3D CAD model of an existing part or product;

- Creation of a 3D CAD model from an existing STL file;

Discuss the project

Clicking on the "Send" button, you consent to the processing of personal data and agree to the privacy policy.

Examples of previous works

Back call

If you have any questions, you can request a call back and our specialists will advise you on all your questions.

Clicking on the "Call me back" button, you consent to the processing of personal data and agree to the privacy policy.