Laser cutting of sheet metal.

Laser cutting of sheet metal is a widespread technology used to cut a metal sheet by exposing the material to a laser beam. This processing method is characterized by high cutting accuracy and a neat edge of the part (there are no burrs, carbon deposits, edge taper and other similar defects). We do laser cutting of metal to order. Modern equipment and experienced staff allow us to carry out projects of any complexity. Laser cutting of sheet metal occurs according to drawings or contours, taking into account the wishes of the customer. When laser cutting sheet metal, the surface is exposed to a powerful, focused beam. In the cut area, the material burns out and evaporates, so a clear, thin cut is formed that does not require mechanical processing. This technology involves the use of high-precision CNC machines. These machines create a high-precision laser beam that cuts metal sheets of various thicknesses.

Factors influencing the cost of laser cutting of sheet metal:

- Material, cost of laser cutting for steel, brass, copper and other metals varies;

- Order volumes;

- Metal thickness;

- The complexity of the cut contour;

The main advantages of laser cutting of sheet metal:

- Stable cleanliness and length of the cut contour;

- Accurate directionality, minimal divergence angle. Allows to make the thinnest cuts;

- High beam power. Laser cutting of sheet metal is much faster compared to other cutting methods;

- Laser cutting can be used for cutting workpieces made of different metals and large thicknesses (for example, aluminum and alloys based on it - up to 20 mm, stainless steel - up to 50 mm);

- When laser cutting metal there is no mechanical impact on the sheet, this eliminates deformation and other damage;

- The cutting process is fully automated, cutting is performed according to the contour loaded into the database using a CNC machine, the cutting tolerance does not exceed 0.05 mm;

- Possibility of manufacturing non-standard, unique products with complex contours and original geometry;

- Another advantage of laser cutting of sheet metal is the minimum waste, since the parts are assembled onto the sheet using specialized programs;

Discuss the project

Clicking on the "Send" button, you consent to the processing of personal data and agree to the privacy policy.

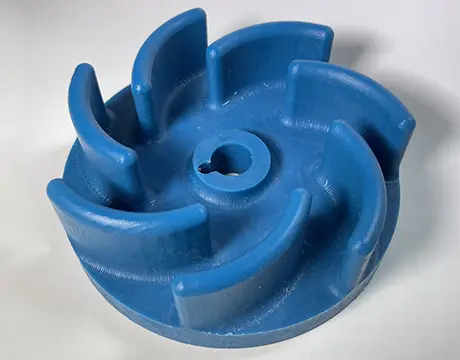

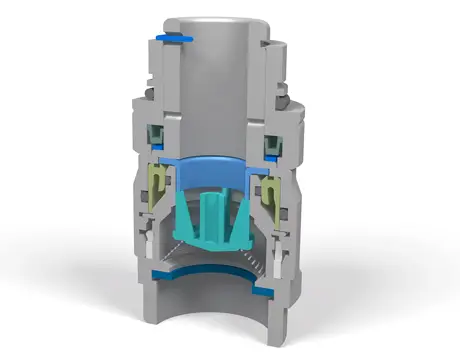

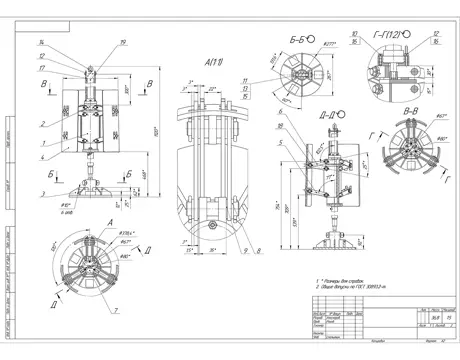

Examples of previous works

Back call

If you have any questions, you can request a call back and our specialists will advise you on all your questions.

Clicking on the "Call me back" button, you consent to the processing of personal data and agree to the privacy policy.