Thread - general information

In the modern world, the most common thread is with a profile angle of 60° degrees. An angle of 60° is used in threads of various standards ISO, DIN, GOST, ANSI. There are other thread standards, they are mainly used in special industries, such as medical, aviation, space technology. The most common thread standards are: DIN, ISO, ANSI, GOST.

Parts in machines, mechanisms, devices, apparatus and structures are connected to each other. Connections are divided into two types: movable and fixed. Fixed connection is a connection of parts that ensures the invariability of their position relative to each other during operation. Welded joints, fasteners are just such. A movable connection is a connection in which the parts have the ability to move relative to each other in working condition. For example, a toothed or swivel joint. Fixed and movable joints are divided into detachable and one-piece, depending on the possibility of dismantling the connection. One-piece connection is a connection that cannot be disconnected without deforming the shape of the parts or the fastener. For example, a welded joint, a soldered joint, etc. Detachable joint is a joint that can be repeatedly disconnected and reconnected without damaging either the parts to be joined or the fasteners. For example, threaded, keyed, toothed, etc.

This section of the site is devoted specifically to threaded connections, with different types of which you have to deal with every day.

1. Thread geometry

Thread is a geometry formed by a helical movement of a flat contour along a cylindrical or conical surface, the trajectory of a flat contour can be perceived as a spiral with a constant pitch lying on this surface (Fig. 1).

2. Thread classification

By purpose, threads can be divided into fastening and running, that is, those that are used in movable joints. There are special threads that have a highly specialized purpose. The thread is divided into tapered and cylindrical, depending on the geometry on which the thread is cut, the same thread can be cut on the outside of the cylinder or cone (external) or in the hole (internal). Depending on the shape of the profile section, the thread can be triangular, trapezoidal, rectangular, round, as well as special. Triangular (the most common) is subdivided into metric, pipe, inch. By step, the thread is divided into coarse, fine and special. Also, the thread can be single-start and multi-start, the direction of the helix can be right-handed or left-handed.

3. Thread profile

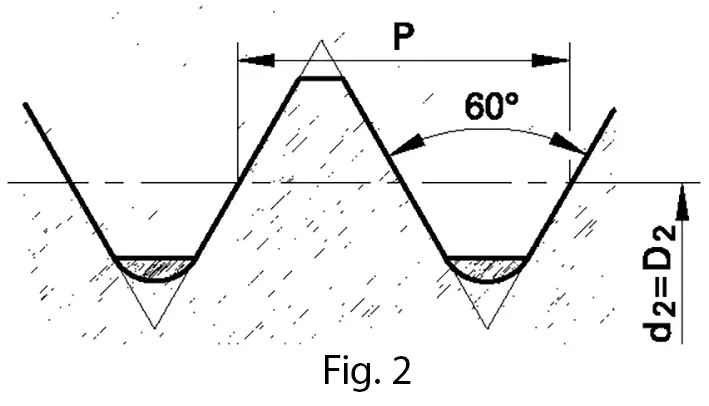

The metric thread has a profile in the form of an equilateral triangle with a profile angle of 60° (Fig. 2).

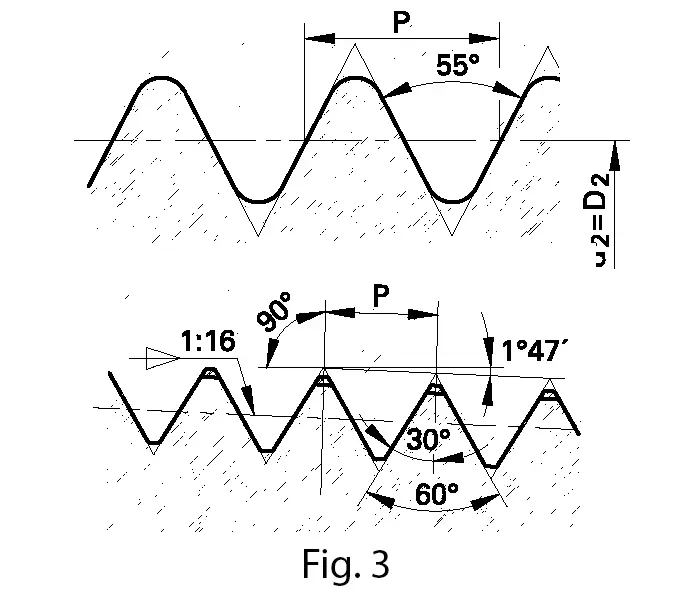

The pipe thread has a profile in the form of an equilateral triangle with an angle of 55°, it can be cylindrical and conical (Fig. 3).

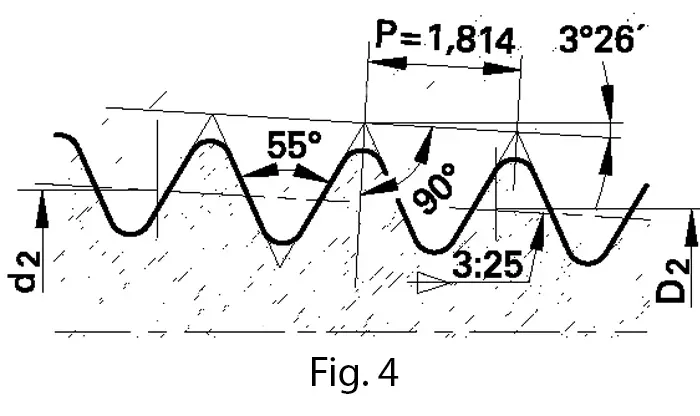

Tapered inch thread (Fig. 4).

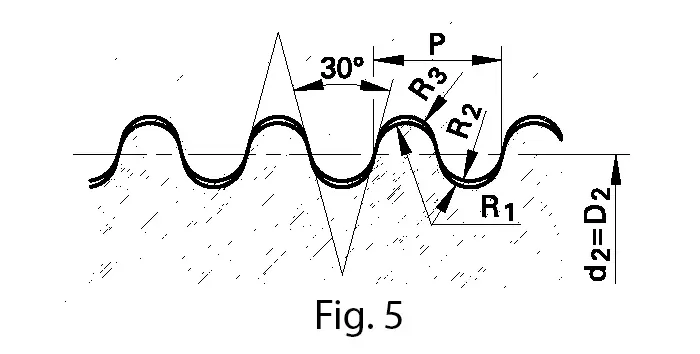

Knuckle thread has a profile in the form of semicircles located tangent to each other (Fig. 5).

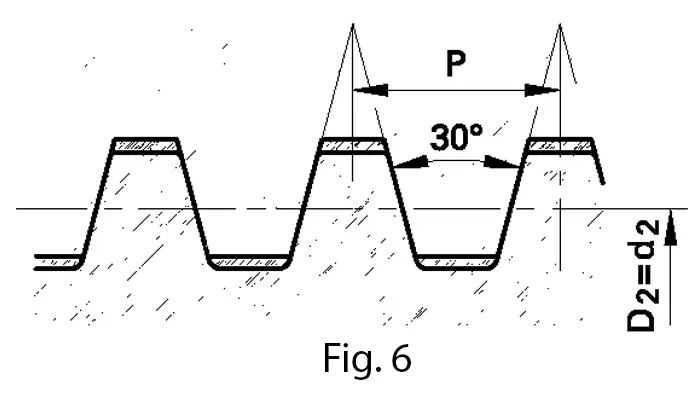

Trapezoidal thread has a trapezoidal profile with an angle of 30° between the sides (Fig. 6).

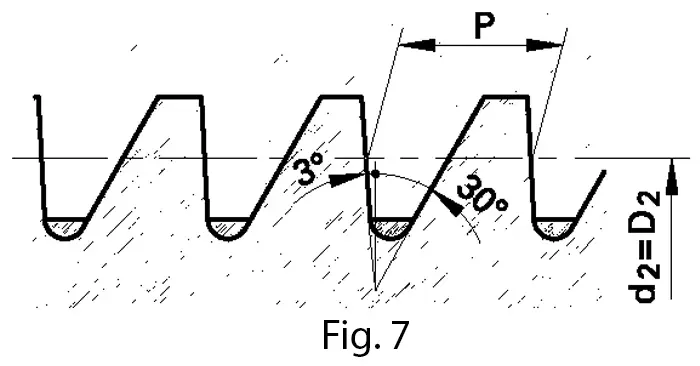

Buttress thread has a profile of a non-equilateral trapezoid with an angle of inclination of the working side of 3° and of the non-working side - 30° (Fig. 7).

Thread pitch (in the drawings designated by the letter P) is the distance between adjacent similar points of the profile in a direction parallel to the thread axis of the same helical surface.

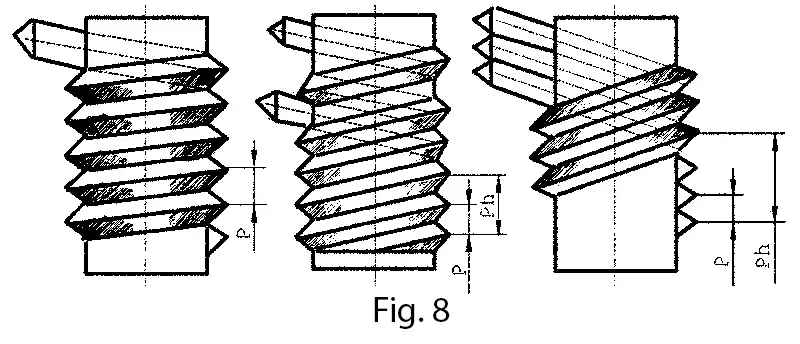

Thread stroke - (Рh) - relative axial movement of the threaded part in one revolution, equal to the multiplication (nР) (the number of thread starts per step). The thread formed by the movement of one profile is called single-start, formed by the movement of two, three or more identical profiles, is called multi-start. In other words, not one spiral is cut at the same time on a rod or hole, but two or three (Fig. 8).

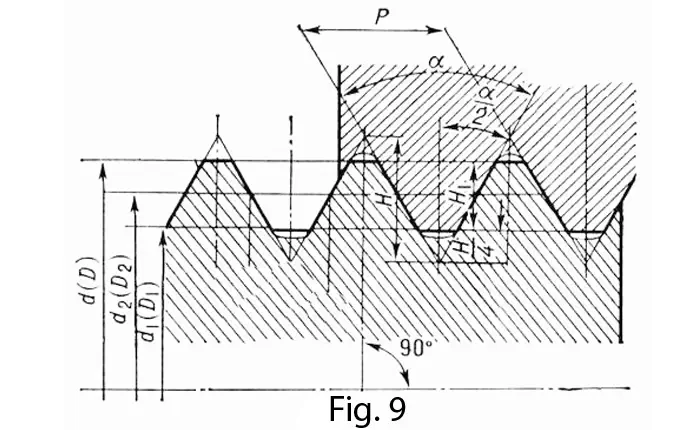

Threads are characterized by three main diameters: outer d (D), inner d1 (D1) and middle d2 (D2). Outside (nominal) diameter d (D) - the diameter of an imaginary cylinder described around the tops of the external (d) or troughs of the internal thread (D). This diameter is the main one for most threads and is the main one in the thread designation. The average diameter d2 (D2) is the diameter of the cylinder, the line of which intersects the thread profile so that its segments formed at the intersection with the groove are equal to half the nominal thread pitch. The inner diameter d1 (D1,), the diameter of the cylinder inscribed in the valleys of the outer (d1,) or the top of the inner thread (D1) (Fig. 9).

Thread designations usually include an alphabetic character indicating the thread type and nominal diameter. Additional data can also be provided such as thread pitch, TPI - threads per inch - the number of threads per inch for inch threads, the number of starts for a multi-start thread, the diameter of the hole for the thread, the direction of the threads (left, right).